About Us

Technobel is ISO 9001:2015 and CE certified organisation aims to provide cutting-edge technology and superior products to industries.

The company engaged in the field of import-export, manufacturing, and trading of Electrical heaters, Ovens, Heating and cooling equipments, Conveyors and automation systems.

In a very short span of time, Technobel has built its Image in Industry, in view of its latest technological know-how, constant research and development, innovative marketing strategies and prompt post-sales support, in order to better serve the distinguished needs of its prestigious clients.

Technobel is leading manufacturers of diversified industrial heating systems. We provide large array of process heating solutions to develop optimal and economic heating solution for customer requirement.

We have expertise in providing electrical heaters and suitable heating methods based on applications. The purpose can be explosive gas heating, highly corrosive acid heating or high temperature air heating, we can guide suitable methods of heating, required watt density, suitable temperature class and suitable terminal box protection etc.

We manufacture heaters with various sheaths including PTFE, PFA, Titanium, incoloy 800, incoloy 840, inconel 600, SS316L, SS321 and SS304L etc.

We manufacturer Electrical heaters, Industrial dryers, Conveyor ovens, Furnaces, rotary drum dryer, thermic fluid heaters, heat pump dryers, Salt bath heating tanks, Pyrolysis reactor, reactors, PTFE heat exchangers. Also, we can do special purpose capacitive level electrodes, Thermocouples, RTDs. We are engaged in providing industrial process heating solutions specifically to oil, gas and renewable energy systems. We have large variety of process heaters with highest capacity like 1000 KW, 1500 KW, 2000 KW AND UP TO 4000 KW Heater in a single flange.

Our HeatEx explosion proof series heaters are used in below processes:

- Feed and product exchanger

- LPG gas vapouriser

- Molten salt bath

- Crude oil heater

- Molecular sieve regeneration

- Thermic fluid heating

- Electrically heated boiler

- Thermal oxidisers

- Fuel gas conditioning

- Fuel oil forwarding

- TEG dehydration

- Hydrocracking and hydrotreating

- Pyrolysis reactor

- Isomerisation

- Continuous catalyst regeneration

- KO drum heating

- Electrolyser

- Waste gas recovery

- Asphalt storage

PTFE, PFA, NFC and Titanium coils

- Cooling coil heat exchanger

- PTFE coil water or thermic fluid heating

- Titanium heating coil

- Serpentine coil

HeatChem series: typical applications

- Chrome plating

- Galvanising

- Nickel plating

- PVD / PFA / PTFE coating

- Sulphuric / phosphoric acid heating

- Electroplating

- Surface finishing

Process heating solutions

- Hot air and hot water generator

- Thermic fluid boiler / heater

- Industrial composite curing oven

- Industrial vacuum oven

- Pyrolysis rotary drum

- Exhaust gas economizer

- Industrial bogie hearth furnace

- Molten salt bath tank and circulation

- Reactor with agitator vessels

- PTFE heat exchangers

Who we are?

Established in the year 2012.

10+ years of industrial expertise.

We are a qualified and experienced management team. We strive for quality with world-leading organisations in industry and our techniques have been proven over the years.

Our Mission:

Our strategy is to develop better heating equipments to serve industries heating needs.

We are focused on fully satisfied customers and employees.

We take all efforts to implement of latest heating techniques in the market.

Our Infrastructure:

We have a dedicated workshop only for manufacturing of electrical heating elements with clean room facility. This ensures clean and dust free environment for heating element production line. Our heater work shop include 4 rolling machines, 6 filling machine, ,2 no of annealing machines resistive type, furnace and induction based, Winding machine, bending machines etc.

We also have separate fabrication area in 15000 Sqft well equipped with loading and unloading cranes and all required machineries for fabrication. Our facility is equipped to make large size industrial ovens and conveyor ovens.

Frequently asked questions:

What is advantage of purchasing from Technobel?

We have competitive advantage providing design, drawing and calculations for heating elements. We have innovative processes that ensure quality that is unmatchable.

Is there any warranty for heaters?

We have competitive advantage providing design, drawing and calculations for heating elements. We have innovative processes.

How is the delivery time?

We take minimum 2 weeks to 4 weeks for delivery of heaters. We take up to 45 days for other machineries and control panels.

What is after sales support?

Installation will be provided by us in case requested while ordering. Also, we provide technician at site depending on location. It may be payable depending on product requirements.

Where is located?

We are on Bangalore Hosur national highway, 15 KM from Hosur and Bangalore city.

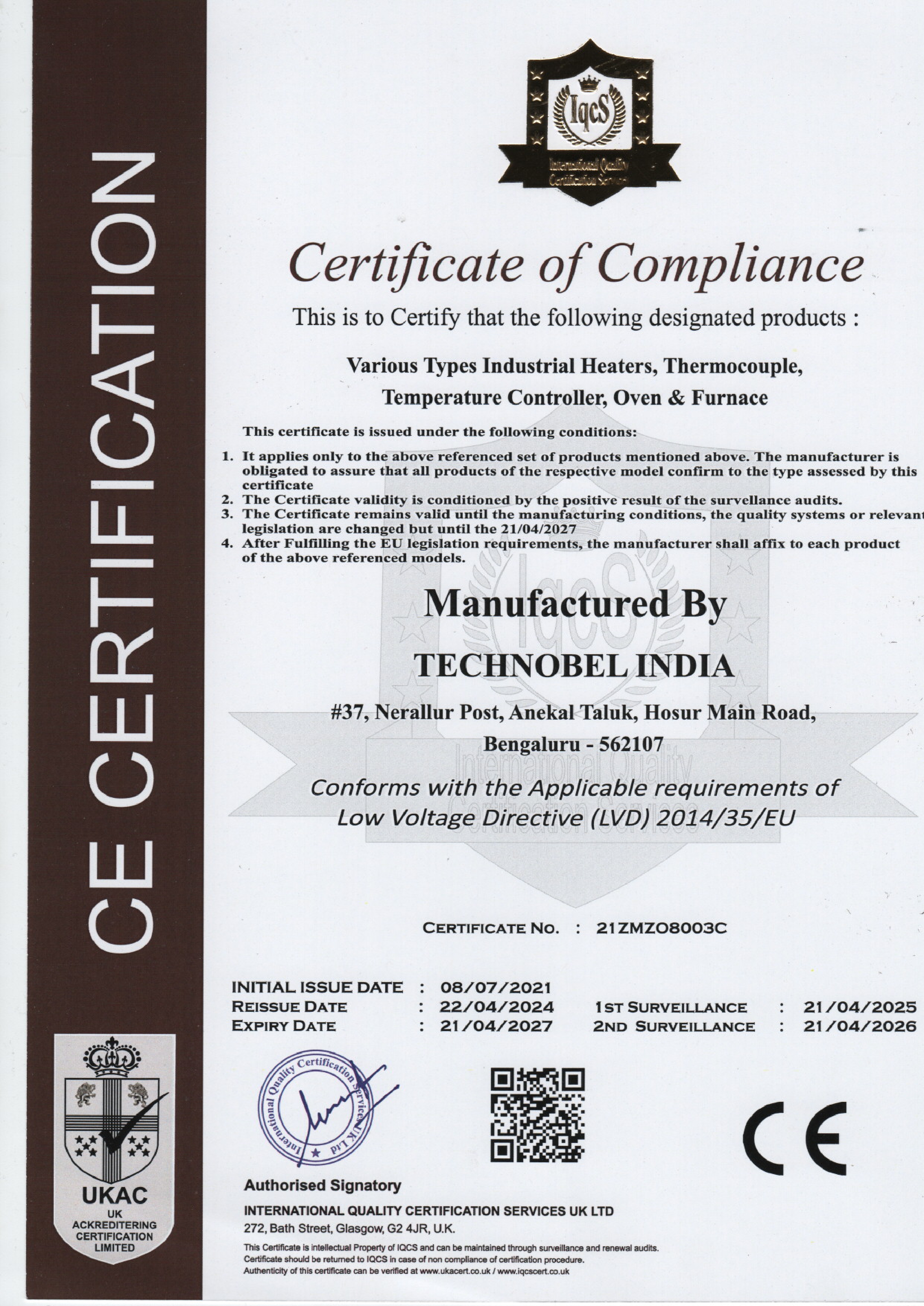

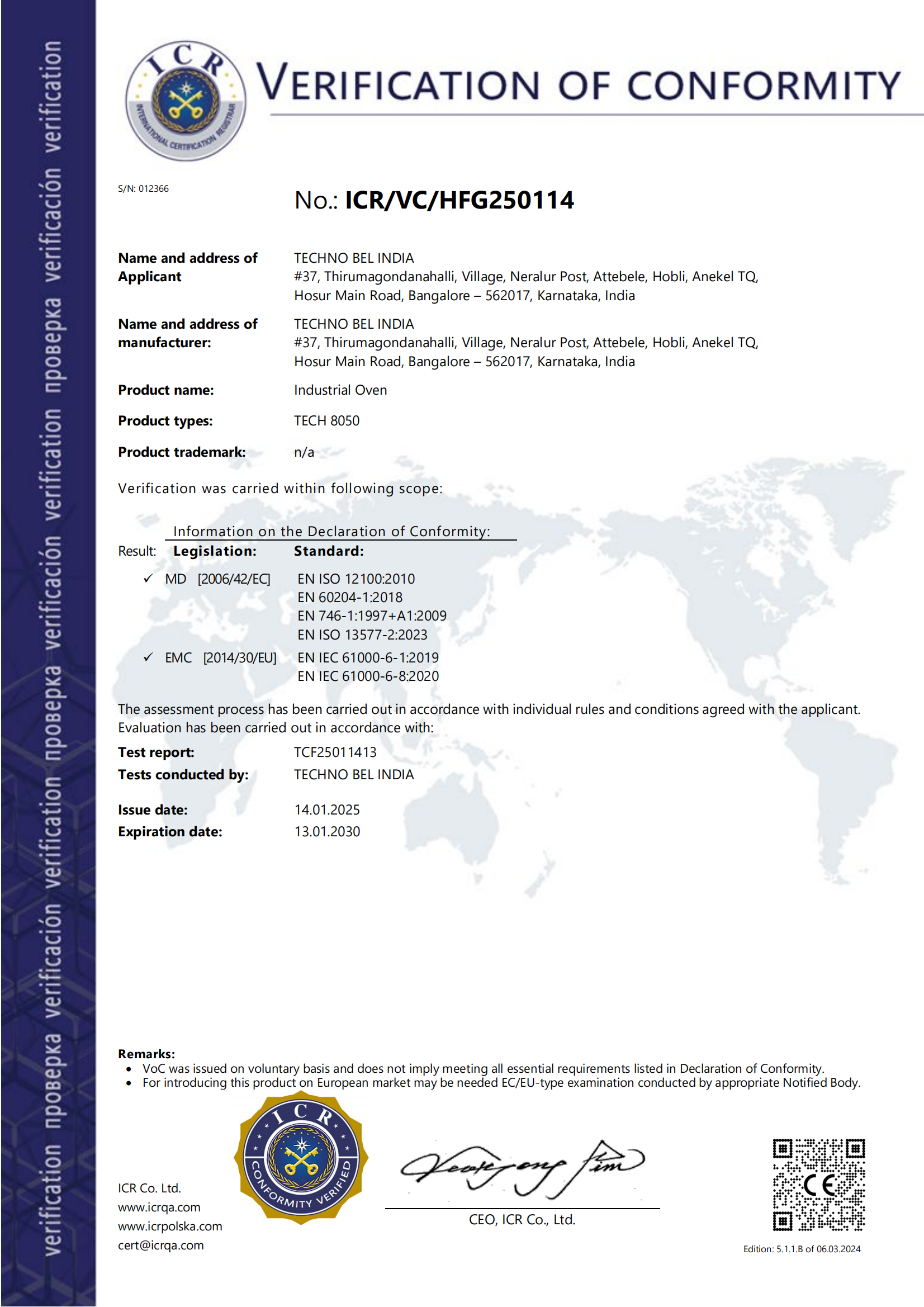

Certificates

Technobel Industries manufactures all kinds of heating products with CE mark which is mandatory for exporting as per European Standards. Technobel is also an ISO 9001:2015 certified organization. Our customer policies and manufacturing aspects ensure to compact with the international standards with best quality.